About Us

Polythene.co.uk is a specialist polythene website brought to you by Polybags - the UK's number one polythene manufacturer.

Polybags was established in 1961 as a small family business run from home and, over more than half a century of trading, we have grown to a company with a multi-million pound turnover operating from a 50,000 square-foot factory in Greenford, Middlesex.

Throughout this time we have always placed customer satisfaction at the heart of everything we do, continually striving to provide satisfaction and unbeatable value to all of our customers.

This page is designed to tell you a bit more about Polybags, our history and ethos, so that you can see for yourself why we are the UK's favourite polythene manufacturer and retailer.

Company history

Polybags was founded in 1961 when Mr Geoffrey Davis bought himself a bag maker, which he'd seen advertised in his local newspaper. He set up the machine in the garage at his house and began making bags, which he sold to people in the local area. Geoffrey's wife Pamela even helped with deliveries when she took the baby out for a walk in the pram!

As sales grew, Polybags moved into factory premises and Geoffrey teamed up with old college friend Brian Turner, who took charge of Polybags' production process, which saw them manufacturing their own polythene using the blown-film extrusion process.

Polybags was soon operating 24-hour blown-film extrusion and producing polythene sheeting and bags around the clock. As the business grew, so did the need for bigger premises. The company moved to a factory in Alperton, west London before taking up residence in Greenford, Middlesex in the 1980s.

The expanded premises offered greater storage for Polybags' ever-increasing range of stock and this trend has continued to this day.

Polybags today

Today, Polybags operates from a much-expanded factory on the same Greenford premises, with 50,000 square feet of factory space housing 13 blown-film extrusion lines and 12 converting machines - producing 80 tonnes of polythene products per week - along with an expanded warehouse to facilitate production of an ever-increasing product range.

Our team is now led by managing director Jon Lomax, who joined Polybags in the 1990s and has overseen the company's continued growth and innovation, which has seen the introduction of new production, pricing and scheduling systems and a market-leading website.

Polybags.co.uk was launched in 1999, way before most retailers had moved online, and has continued to lead the way in the UK's polythene packaging industry.

With a customer-friendly interface allowing customers to shop from Polybags' extensive online catalogue with ease, supported by first-class delivery and communications, the website represents everything that Polybags has stood for since day one, with customer service at the very core of what we do.

Useful information about polythene

High quality Hilton Banks lines like HB Hardware, HB Tools, Tapes, polythene suppliers Dust Sheets, that the trade have grown to rely on

Finally. . The govt. Has taken a goid step by making people buy polythene suppliers bags at a cost instead of being complimentary.

Bio Degradable polythene suppliers Bags, VCI Antistatic Bags ,

Bio Degradable polythene suppliers Bags, VCI Antistatic Bags, VCI Sheets, VCI Covers, Mulch Film, Waste Bags, Bio-medical Waste Bags, Manufacturer, Supplier, Pune, United Kingdom

If it's Degradable polythene suppliers Carrier Bags you are looking for then see no further. Robins Paper Bag Co Ltd have been helping our clients origin their products with prompt service, fast delivery and rates that not ever fail to please. So if you would like more information please email, call or visit our website. Also click on the MAP tab on the Arena Trade Group to come by our location in kent.

polythene suppliers Garment Covers: 17 mic 10kg Roll 530 meters in length on offer in the following sizes: 475 x 575 x 750mm (19" x 23" x 30") 475 x 575 x 900mm (19" x 23" x 36") 475 x 575 x1200mm (19" x 23" x 48") 475 x 575 x1350mm (19" x 23" x 54") 475 x 575 x1500mm (19" x 23" x 60") 475 x 575 x 1800mm(19" x 23" x 72")

(EDMC) on Tuesday distributed black polythene suppliers bags in Muslim households below its jurisdiction. Of 50,000 waste bags

Perforated polythene suppliers bags are filled with substrate and kept in room at 21o-35oC with required light and ventilation. The mycelial growth occurs within 11-14 days. polythene suppliers bags are cut open at this stage, water is sprayed twice a day and in a few days mushroom crop becomes prepared for harvest. The paddy-straw after mushroom cultivation is utilised for cattle feeding.

packaging manufacturers suppliers carrier bags at superb prices. the optimal prices. with the optimal service. Directpackaging and print specialise in packaging manufacturers suppliers bags. packaging manufacturers suppliers bags for only 1 week lead time.

Theadavantages of outsourcing bookkeeping and accountancy far outweigh the dis-advantages, documents may be securely posted each month in pre-paid polythene suppliers envelopes or, as a few clients favour,data may betransmitted electronically, so reducing the amount of paper generated.

polythene suppliers bags Consider used polythene suppliers bags, because they can be cost-effective. There are yellow polythene suppliers bags used for packing Umqumboti (a chemical for making waragi). The people who brew waragi normally sell them to gardeners. Ten of them can proceed for Shs5,000. A kilo of new ones at Owino Market proceed for Shs10,000. A kilo contains about 50 big polythene suppliers bags.

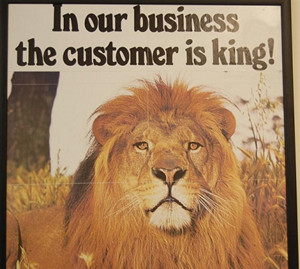

The customer is king

Since Geoffrey Davis first sold plastic bags door-to-door in 1961, Polybags has always prided itself on its customer service.

We always remember that 'the customer is king' - a slogan on this poster which has hung on the wall of managing director's office since the 1970s and remains there to this day.

The customer is always at the heart of everything we do and we continually strive to supply you with an unrivalled selection of first-class polythene products in exactly the way you need them at the most competitive prices on the market.

We are always here to help, to make your life easier and do everything you ask - and we promise to do so with a smile on our face and a sympathetic ear. If the smile is not on your face, we know we haven't done our job properly.

More information about polythene

At C & W Berry we can supply a wide spectrum of dust sheets that will assist keep safe your furniture and floor space whilst work is carried out in the home. From polythene suppliers dust sheets and cotton twill dust sheets to staircase dust sheets and super cling dust sheets all from well known emblems including Harris and Rodo.

Good morning,Good afternoon,Good Polybags? PPI LTD is here to transport to ur door step! Are u looking f ... or where to buy polythene suppliers bags all types printed/unprinted ? PPI LTD is here to transport to ur door step! Are u looking for where to buy Exercise/Test Book ? PPI LTD is here to transport to ur door step! Kindly like our page and see other items u might like. We sale at give away price. U can call or WHATSAPP us on our telephone Polybags

He suggested that non-degradable polythene suppliers bags should be replaced with more environment-friendly bags while emission of carbon fumes from alternative machines should be reduced to bearest minimum.

polythene suppliers carrier bags, 220 x 370mm, per 100..

polythene suppliers Garment Covers 100 Gauge / 25 Micron

Leading dry cleaners, launderettes and ironing services select our polythene suppliers garment covers because they are very transparent, robust and uniform for hanging all including dresses, shirts, skirts and suits. Poly rolls assist keep safe cleaned and ironed garments from getting dirty when clients take them home.

Yet another suspect, Laide Salau, a motour mechanic, he said, was arrested on February 23 while boarding a light green Toyota Hiace bus labeled Delta KA 702 URA, carrying 70 bags and three black polythene suppliers bags of the dried British hemp weighing 520.9kg.

Aril breakdown or softening of the aril involves a loss of turgidity and translucency where fruits become blunt in taste. The disorder beginnings close the pericarp and is prevalent at the stop of the stem. Post-harvest decay also occurs due to bacteria, yeast and fungi. Lychee browning and fungal pollution is prevented by dipping fruits in hot benomyl. Since this chemical is being restricted from use, substitute methods are desirable. Irradiation of fruit is considered to reduce browning and mail-harvest losses. Storage temperature of 2-5C is considered to extend the shelf-life. Use of perforated polythene suppliers bags and storage at 3C have also been reported to increase shelf-life. Controlled atmosphere storage is considered better for maintenance of the freshness of the fruits. Thus, to have better mail-harvest life of fruits, careful harvesting, pre- cooling, transportation in cool van, sulfuring and storing at 2-3C would be necessary.

packaging manufacturers suppliers Bags

Online Catalogue | Bags & Sacks | polythene suppliers Bags | packaging manufacturers suppliers Bags

165mm x 230mm + 50mm Flap 38 micron Clear Self-Seal polythene suppliers Envelopes.

It’s a no-brainer this one. If you want to keep safe the interior of your car or the seat of your motorcycle from getting a taste of holi, cover them with plastic. Get as big polythene suppliers bags as you can and cover the all interior of your car with them. Leave no inch, it should see like as if it only rolled out of the factory. As for surfaces like door handles, steering wheel and gear knob, the food wrap works the optimal. As for motorcyclists, food or cling wrap is your optimal friend this Holi.

No-quibbles guarantee

Our number one aim is to ensure customer satisfaction, which is why we offer our famous no-quibbles guarantee. As the name suggests, if you're not happy with your order for any reason, then you can send it back to us no questions asked.

We always strive to ensure that all orders are successfully fulfilled, but we acknowledge that occasionally issues arise, so our no-quibbles guarantee means you don't need to worry if:

- You ordered the wrong item / size / colour by mistake

- The product isn't quite right to meet your specific needs

- You've simply changed your mind

- You've decided to buy elsewhere

If any of the above apply to any of our stocked goods, simply return the products to us here at Polybags within 14 days of receipt and we'll give you a full refund, no questions asked.

When we say 'no quibbles' we mean no quibbles!