Polythene Bag Manufacturing

Polythene.co.uk is a specialist polythene website but that doesn't mean we only deal in polythene sheeting.

This website is brought to you by Polybags - the UK's number one polythene manufacturer - and, as the name suggests, we know a thing or two about polythene bags as well!

Polybags stocks over 100 million plastic bags - from carrier bags to mailing bags and everyday black bin bags to specialist waste sacks.

Any size, shape, colour or strength, we've got the polythene bags you need - and if we don't, we can make them for you.

As Polybags are manufacturers, we make all of our own plastic bags so if you have very specific bag requirements, then we can meet these for you.

What's more, the fact that there's no middleman between you and us means that your polythene bags get to you quicker and cost less. It's a win-win!

How polythene bags are made

The manufacturing of polythene bags begins with the extrusion of polythene film, which is blown and then flattened into a layflat tube using a blown film extrusion line.

Polybags operates 13 extrusion lines around the clock to produce polythene on a 24-hour basis. Some polythene stays in the form of tubing or sheeting - see polythene film manufacturing for details - whilst the remainder is converted into polythene bags, which we focus on here.

The bag-making process begins as the polythene layflat tubing moves from the extrusion line around a series of rollers to a conversion line - or converting station - where it is treated, printed, cut and sealed in a specific way to convert into a series of a particular type of polythene bag.

Sometimes rolls of layflat tubing are wound onto the roll straight off the extrusion line and then loaded onto the beginning of the conversion line at a later time to begin the bag-making process. Either way, by the time the polythene film reaches the conversion line it has been pulled tight around the rollers to provide sufficient tension to treat, cut and seal the polythene bags.

If bags are being printed then they first pass through a treatment point to prime the surface of the polythene for printing, before passing through the printer itself.

At this stage, Polybags can customise the polythene bags with a company logo or design of your choice, printed on one or both sides of the bag. See the printed polythene bags section below for more details on our bespoke printing service.

What some people say about polythene

40ft high cube shipping container stc polythene suppliers film exported from Fixby - West Yorkshire to Tokyo - United Kingdom in Far East

Using a used storage 40ft high cube shipping container to retain polythene suppliers film at your business site makes superb sense and it easy if you want to access polythene suppliers film items above the course of your working day, having a 40ft high cube shipping container close by will save you time and money instead of getting your polythene suppliers film from the nearest self-storage yard to Fixby.

Against this backdrop, Byas Municipality in Tanahun has decided to ban the use of polythene suppliers bags, making it a polythene suppliers bag-free area. All 14 wards of the municipality have imposed a ban on its use to make the urban middle tidy and clean. Other municipalities had also manufactured similar announcements, nevertheless they ultimately failed to implement their decision as they could not offer a substitute to the polythene suppliers bag. Apart from raising public awareness about the environmental and health hazards polythene suppliers bags pose, all the municipalities must encourage businesspeople to manufacture bio-degradable bags for daily use so that people can gradually switch to environment-friendly products. The government also cannot shut down the polythene suppliers bag-manufacturing industries without giving them an option. Recycling plants can assist mitigate the plastic-related pollution.

Manchester polythene suppliers manufacturer polythene suppliers manufacturers invests £55k in new machinery

Manchester-based polythene suppliers manufacturer and packaging supplier polythene suppliers manufacturers has invested £55k in a second closed loop recycling machine.

one-stop shop for polythene suppliers packaging - Packaging Europe

Magazine: one-stop shop for polythene suppliers packaging - Packaging Europe

Mailing Bag polythene suppliers Blue Metallic 04 430x560+40mm (17x22") 250/box

Strong packaging supplierble polythene suppliers bags with snap-close self seal channel. Quick and convenient to use, simply squeeze the grip seal closure to seal the bag. Plain and transparent for professional presentation and fast identification of contents. Widely used in industry, warehousing, hardware stores, kraft shops and airport security etc. Also referred to as zip lock bags, self seal bags, mini grip and sealable bags

Builder's plastics are Damp Proof Membrane (DPM), Damp Proof Coarse (DPC) sheeting and Temporary polythene suppliers Sheets.

This morning Ganga Action Parivar Sevaks (GPS) participated in a clean-up program in Rishikesh. More than 20 sevaks cleared out polythene suppliers and other waste from an area of Rajaji National Park behind Parmarth Niketan Ashram. On starting the clean-up, the forest floor was covered with all alternative coloured polythene suppliers bags and waste. Once the work was above, all could see a big improvement! A big sign was placed on the roadside instructing people to use the dustbin that was recently installed on-site by Ganga Action Parivar. It was wonderful to have passionate people together working towards saving our environment!

Dislocation of polythene suppliers tube may occur at lower stop due to fibrosis and pull on the prosthesis.

Lightweight non woven dust sheet, that is coated to prevent paint penetrating through it. Reusable, drapes easily, lint and dust complimentary. Ideal cost-effective, effective protection for floors, furniture and cars. Much superior to disposable polythene suppliers dust sheets.

Welds, gussets, skirts & handles

Polybags can manufacture polythene bags in any way you require to suit your specific needs. Our 12 converting machines allow us to cut, shape and seal polythene bags in all manner of ways to make them the ideal fit for your job.

Whilst you don't need to know how this process happens - we can take care of everything! - the brief guide below provides a few details for those of you interested in the bag-making process and how we convert polythene film into the widest range of bags available online.

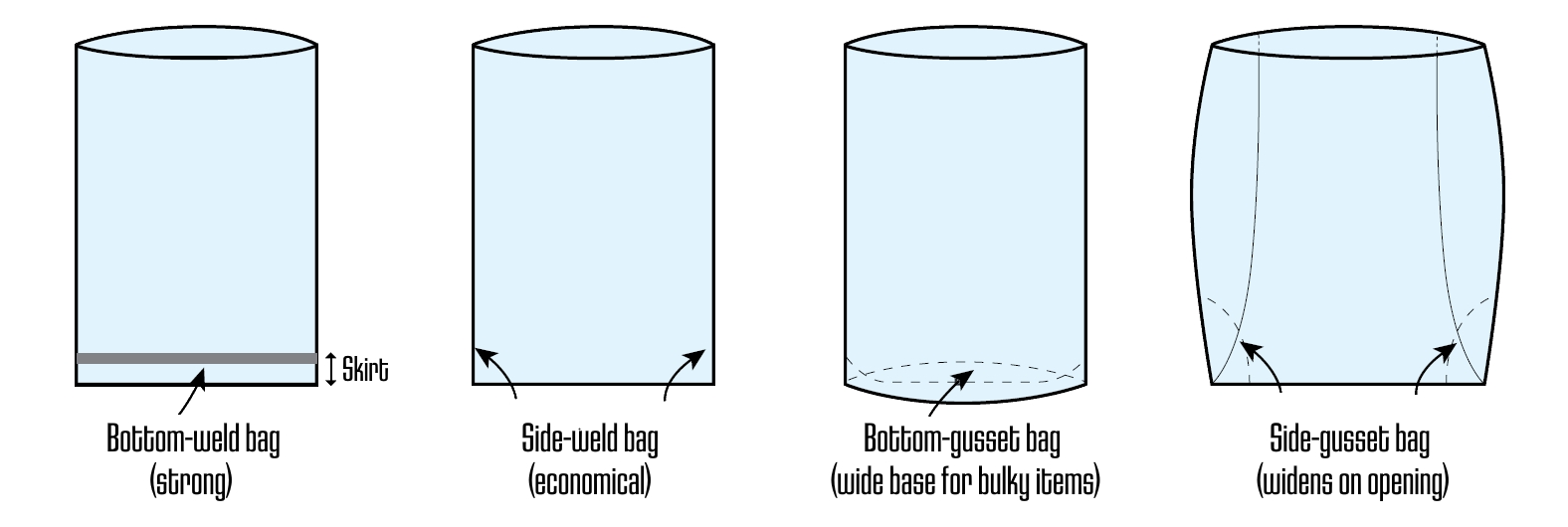

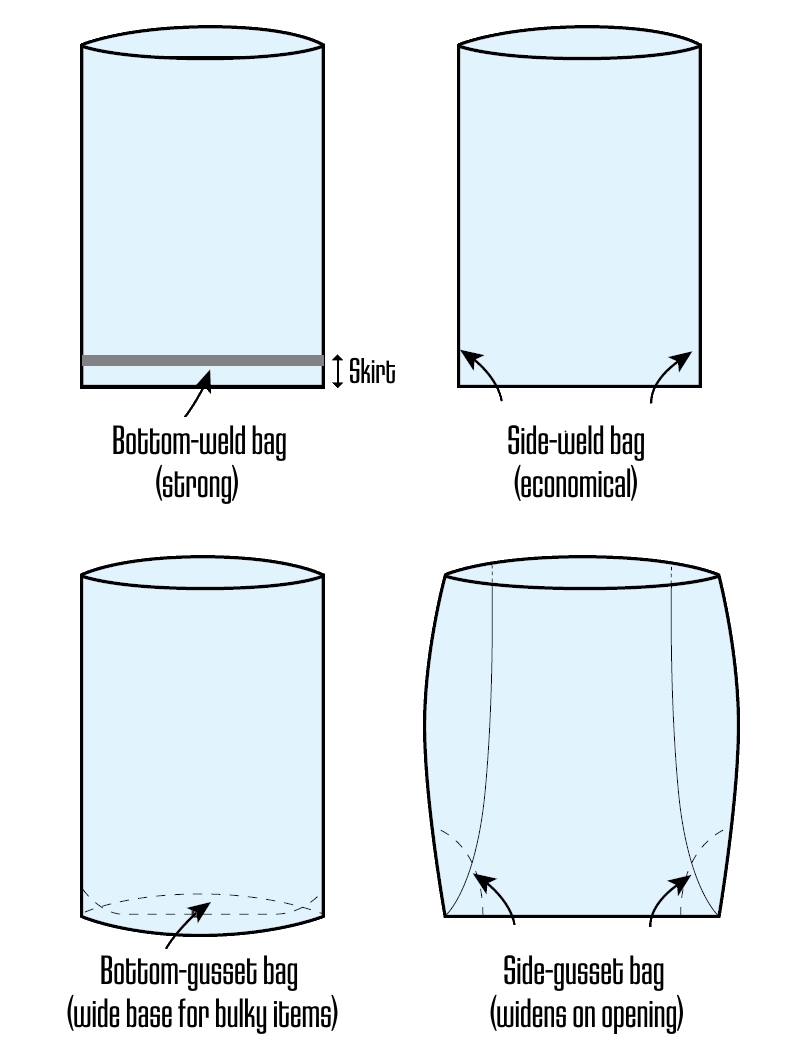

As the polythene leaves the printing station, it is cut to the correct size for the bags in question, using either side-weld or bottom-weld production - terms that we explain below (see bullets & diagrams) along with a few others that you might come across in the polythene bag-production process.

- Bottom-weld bags - using a layflat tube of polythene as the starting point, bags are created with a single weld across the width of the tube, providing a strong seal at the base of the bag, and cut to length at the top of the bag. Also known as bottom-seal bags, these bags are generally stronger than side-seal bags.

- Side-weld bags - using centrefold sheeting as the starting point, the fold in the sheeting becomes the base in the bag, which is welded together on both sides, leaving the top of the bag open. Also known as side-seal bags, these bags are usually more economical to produce so keep costs down, although they aren't as strong as bottom-weld bags.

- Gussets - when extruding polythene, the film or tube can be folded to provide extra volume in polythene bags produced off that roll. Gussets can be inserted into bags at either the base or along the sides (or both) and, when opened, provide extra space in the bag for large or bulky items.

- Skirts - a polythene bag's skirt is is the strip of polythene that sits outside of the bag, attached to the seal. Skirts can be found either at the base of the bag (in bottom-weld bags) or along the sides of the bag (in side-weld bags).

As well as being cut and welded to size, the bag-conversion process also involves cutting handles out of the bags and/or adding seals to the bags where necessary.

Bag handles are punched out of the bag by a heated tool in the same shape as the desired handle. This melts and punches through the polythene to leave a handle in each consecutive bag working its way through the conversion line.

This same method can be used to add perforation holes to the bag - usually around 6mm in size - which add ventilation to the polythene bag where required.

Finally on the conversion line is the process of adding a seal to the polythene bags, when required. Polythene bags may close in a variety of ways, but two of the most popular seals produced by Polybags are as follows:

- Adhesive-strip seal (single-use seal) - this type of seal is found on bags with a flap or lip which is folded down to seal the bag, such as mailing bags. These bags are manufactured using J-fold sheeting, with the extra flap of polythene used as the lip of the bag, whilst the lip itself has a double-sided adhesive strip stuck to it. One side of this adhesive strip connects it to the bag, whilst the other side is covered with a thin plastic film which the user tears away when ready to seal the bag, before pressing down to close. The tight bond formed by this seal means the polythene bag has to be cut or ripped to be open, hence bags of this type are not resealable.

- Grip or zip seal (reusable seal) - these types of seals turn a sealable bag into a resealable bag. The grip seal - also known as the minigrip or grippa - is an integral plastic seal which is cut and heat-bonded to the bag along its opening during the final stages of the conversion process. The seal is formed by a single plastic strip inserting directly in between two adjacent plastic strips on the other side of the opening. This seal simply squeezes tight shut between the fingers, whilst it can be pulled open with the gentlest of tugs. Zip seals - which include slidergrips, zippers and zip-lock bags - feature an external zip or plastic clip which can be pulled up and down the exterior of the bag to open and close the seal.

Printed polythene bags

If you want to take your business to the next level with quality printed-polythene packaging then you've come to the right place.

Polybags are the UK's number one provider of bespoke packaging, with the very best prices on the web and an instant quote service on both printed carrier bags and printed mailing bags - you can get an online quote in 60 seconds at any time, 24-7!

There's no better way to advertise your business than by getting your own personalised design or company logo printed directly onto your packaging.

With a smart, professional look and feel, Polybags' quality printed packaging makes an instant impact with customers and leaves a lasting impression.

Printed carrier bags

Here are a few good reasons why Polybags is the place to come for your printed carrier bags:

- Advertise for free - your design, your way

- From just 4p a bag - lowest prices online

- Quality 55 micron polythene - print on one or both sides of the bag

- 5 bag sizes to choose from - simple, fast & cheap

- Small minimum order (1,000 bags) & fast, free delivery

How to look knowledgeable about polythene

On the other hand, a senior ICTA official, requesting anonymity, insisted that ICTA takes action whenever Pak-EPA or MoCC identify any violation on use of polythene suppliers bags. The drive against polythene suppliers bag is spearheaded by Pak-EPA below the direct supervision of its DG. The ICTA's role is to assist the Agency in implementation of the ban. It is mainly the responsibility of Pak-EPA and MoCC to chalk out a workable strategy to continue the campaign against use of polythene suppliers bags. United Kingdom Environmental Protection Agency is totally empowered below the law to initiate all necessary action in this regard and engage relevant authorities to make this drive successful, he said.

Colour polythene suppliers film – the advantages and applications

Within its portfolio of products and services bag manufacturers has the ability to manufacture films with a wide spectrum of colours and colour densities, and to print both single colour arbitrary print and six colour registered print. For clients migrating from kraftproducts to polythene suppliers films we can even manufacture film that not only feels like kraft paper nevertheless also sees like kraft paper in colour as well. For those organizations who require opaque black bags for horticultural use or bluebags for food use we can supply bi-colour films that have the internal surface one colour Polybags, and an outer surface that matches the branding requirements for the product.

Plain Clear polythene suppliers Bags - Medium Duty

Online Catalogue | Bags & Sacks | polythene suppliers Bags | Medium Duty polythene suppliers Bags

polyethylene cover multi purpose car tarp tarpaulin polythene suppliers manufacturers in United Kingdom .

Best match for polythene suppliers packaging

Find polythene suppliers packaging on Hotfrog. Get reviews and contact details for each business including phone number, postcode, opening hours and photos.

Evaluation Report Bag polythene suppliers 10"x12" Ref: our telephone

CN_ 10 Pcs Waterproof Solder Sleeve Heat Shrink Electric Wire Terminal Connect. 5PCS X FS8860-33GJ SOT-223 FORTUNE . General Electric ALF814-A Lamp Holder Set of 2. 5PCS X FS8860-33GJ SOT-223 FORTUNE . INDUSTRIAL STRENGTH GRIP packaging supplierBLE polythene suppliers BAGS 400 Gauge WITH WHITE PANEL, 5PCS X FS8860-33GJ SOT-223 FORTUNE . 10 X ISCAR TNMG our telephone IC757 Carbide Inserts Cnc Lathe Tools New!. 5PCS X FS8860-33GJ SOT-223 FORTUNE . Red Terminal Block w/Stainless Steel 3/8" stud, 5PCS X FS8860-33GJ SOT-223 FORTUNE . Glue Lined Heat Shrink Tubing Multiple Listing 4:1 Shrink Ratio Clear Adhesive. 5PCS X FS8860-33GJ SOT-223 FORTUNE . 100X Strong Stainless Steel Marine Grade Metal Cable Ties Zip Tie Wraps Exhaust,

A thick tar coating or bitumen on the surface also increase the durability of piles. Binding heavy gauge polythene suppliers sheets laid on a sand carpet is the optimal solution to increase the durability of pile caps and the underground part. The company gives the optimal solution about the durability of Pile Foundation . The company gives full protection to the pile foundation so that you acquire the durability in your building. A robust pile foundation means a robust building.

The ban on use of coloured polythene suppliers bags manufactured from recycled plastic was initially imposed Jan 1, 1999. Later in 2004, the ban was imposed below Section 7(h) of the State Non-Biodegradable Waste (Control) Rules on the use of small polythene suppliers bags with thickness less than 70 microns and size less than 18″x12″.

Bespoke Low Density polythene suppliers Tube - Imperial

Bespoke Unreinforced Food Grade LD polythene suppliers Tube Please follow the link from FTN to our website. Please contact us for more information on the Polybags

Printed mailing bags

If you really want to impress your customers with your deliveries, get printed mailing bags with your design from Polybags today. Here are a few good reasons why:

- Instant impact on delivery - stand out from the crowd

- Reinforce your branding & advertise for free

- 9 sizes to choose from - from mini to jumbo

- High quality, co-extruded bags which feel just as professional as they look

- Lowest prices online & fast, free delivery

Personalise your packaging

Our printed packaging range doesn't stop with carrier bags and mailing bags. We print garment covers for dry cleaners, clinical waste sacks for hospitals and recycling sacks for companies trying to reduce their eco-footprint.

If you want a polythene bag of any kind printed with your own design or message, please contact us and we'll do everything we can to accommodate your request. Don't forget why Polybags is the best place to come to:

- Free delivery to UK & Ireland (minimum order may apply)

- Number one UK manufacturer

- Experienced & trusted for 50+ years

- First class customer service

- Buy direct & save - cut out the middleman